A personal fall arrest system should be inspected monthly by – Ensuring the safety of individuals working at heights is paramount, and a personal fall arrest system (PFAS) plays a critical role in preventing falls and minimizing the risk of injury. Regular inspections of PFAS are essential to ensure their effectiveness and compliance with safety regulations.

This article delves into the importance of monthly PFAS inspections, providing detailed guidance on inspection procedures, documentation, and personnel training.

Monthly inspections are crucial for identifying potential hazards, such as damage, wear, or corrosion, that may compromise the integrity of the PFAS. By conducting regular inspections, organizations can proactively address these issues, preventing accidents and ensuring the safety of their workforce.

Monthly Inspection Requirement for Personal Fall Arrest Systems (PFAS)

Regular monthly inspections of personal fall arrest systems (PFAS) are crucial for ensuring the safety of workers exposed to fall hazards. Neglecting these inspections can have severe consequences, including accidents, injuries, and even fatalities.

Inspection Procedures

Monthly PFAS inspections should follow a detailed procedure to ensure thoroughness and accuracy. The following steps provide a general guideline:

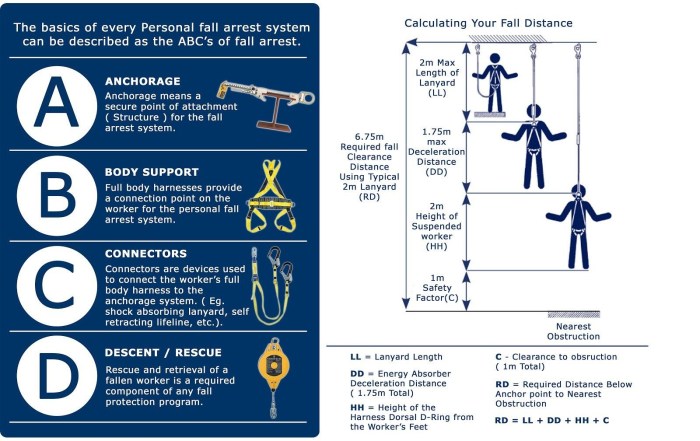

- Inspect Harnesses:Check for damage to straps, buckles, and stitching. Ensure all buckles are secure and free of corrosion.

- Inspect Lanyards:Examine for cuts, abrasions, or fraying. Check the shock-absorbing pack for any signs of deployment.

- Inspect Connectors:Ensure all connectors, including carabiners, hooks, and snap hooks, are free of cracks, bends, or damage. Verify proper operation of locking mechanisms.

- Inspect Other Components:Check any other components of the PFAS, such as lifelines, retractors, and anchor points, for signs of wear, damage, or improper installation.

Inspection Documentation

It is essential to document the results of PFAS inspections to maintain a record of their condition and any necessary repairs or replacements. The following methods can be used:

- Inspection Logs:Create a dedicated logbook or database to record inspection dates, findings, and actions taken.

- Inspection Checklists:Use standardized checklists that guide inspectors through the inspection process and provide a structured record of results.

Personnel Training, A personal fall arrest system should be inspected monthly by

Personnel responsible for conducting PFAS inspections must receive adequate training to ensure they are competent in performing the task. Training programs should cover:

- Inspection procedures and criteria

- Identification of common defects and hazards

- Proper documentation and record-keeping

- Frequency of inspections

Inspection Frequency

The frequency of PFAS inspections is determined by several factors, including:

- Usage:More frequent use requires more frequent inspections.

- Environment:Harsh environments, such as extreme temperatures or corrosive substances, necessitate more frequent inspections.

- Industry Standards:Some industries have specific regulations regarding the frequency of PFAS inspections.

Inspection Responsibility

Assigning clear roles and responsibilities for PFAS inspections is crucial. This may involve:

- Inspectors:Trained personnel responsible for conducting inspections.

- Supervisors:Responsible for ensuring inspections are conducted regularly and documented.

- Safety Managers:Responsible for establishing inspection protocols and monitoring compliance.

Question Bank: A Personal Fall Arrest System Should Be Inspected Monthly By

How often should a personal fall arrest system be inspected?

Monthly inspections are recommended to ensure the system’s integrity and compliance with safety regulations.

Who is responsible for inspecting a personal fall arrest system?

Trained and competent personnel should conduct the inspections, as they have the necessary knowledge and skills to identify potential hazards.

What are the consequences of neglecting regular inspections?

Neglecting regular inspections can lead to undetected damage or wear, increasing the risk of system failure and potential injury to the user.